Maintaining your BUNN coffee maker is essential for delivering high-quality brews that keep your customers satisfied. One crucial aspect of this maintenance is descaling, a process that removes mineral buildup from the machine’s components. As a business owner, understanding how to properly descale your coffee maker not only prolongs its lifespan but also ensures optimal coffee taste and efficiency. In the following chapters, we’ll explore the essential steps to effectively descale your BUNN coffee maker, the importance of regular descaling for maintenance, and identify common problems that may arise during the process, along with their solutions.

Descaling a BUNN Coffee Maker: A Practical and Gentle Guide

Mineral deposits from hard water are persistent enemies of speed and flavor. In a busy kitchen, a coffee maker that brews slowly or tastes flat can feel like a nuisance, but the impact runs deeper: scale can alter heat, flow, and extraction. Descaling is more than a cosmetic reset; it’s maintenance that restores the internal pathways so water travels as the designer intended. When minerals cling to the heating element and narrow tubing, they act like tiny dam walls, impeding flow and absorbing heat. The result is longer brew times, uneven temperatures, and a cup that lacks brightness. Descaling helps preserve performance and extend the life of your brewer.

Descaling a BUNN is straightforward: circulate a descaler through the machine and then flush with clean water. Use a descaler made for coffee equipment, follow manufacturer guidance, and rinse until no residue remains. A household option like white vinegar is sometimes discussed, but a dedicated coffee descaler is gentler on seals and gaskets and less likely to leave lingering flavors. Mix the descaler with water per the product directions, and run it through the machine as you would a normal brew, with the basket empty. The aim is to simulate normal operation while the cleaning chemistry does the work of dissolving mineral scale and flushing it away. The process is practical, repeatable, and designed to protect long-term performance.

Before you begin, gather your supplies: a proper descaler for coffee makers, a clean water source, and a clean reservoir. Avoid abrasive cleaners or harsh chemicals that could damage seals or plastic parts. If you choose a non-dedicated product, ensure it’s safe for machine components and follow the cautions on the label. Some models allow you to remove the reservoir for easier filling; others require you to drain it in place. The goal is to observe the descaling solution moving through every conduit and ensure you rinse thoroughly before the next brew.

The preparation phase is where precision matters. Turn off and unplug the machine, and remove the water reservoir if possible. Pour in the recommended descaler solution and dilute with water as directed. Typical guidance places descaler at one part to three parts water, but follow your product’s exact instructions. For a larger BUNN model, a common ratio might translate to about 500 ml of descaler concentrate and 1500 ml of water, enough to run through the system in one or two cycles.

With the reservoir in place and the solution prepared, start the descaling cycle. Reconnect power and initiate the cleaning sequence according to your model’s instructions. On many BUNN machines, this involves a specific control sequence or a prolonged press of the brew button to start a cleansing mode. The duration varies by model, typically 15 to 30 minutes, and the liquid will circulate through the heating element and tubes. Observe the process; you may notice the reservoir level dropping as the system runs through your descaling routine.

Once the cycle completes, allow the solution to sit for a short soak, usually 15 to 30 minutes, to give the chemistry time to work on stubborn scale. After the soak, run the cycle again to maximize cleaning. Then flush with clean water by running two or more full water brews. The goal is to remove all chemical residues and any loosened deposits, so the first post-descaling pot tastes clean and neutral.

While the machine is cycling, take a moment to wipe the exterior and inspect removable parts. Clean the drip head, carafe, lid, and filter basket with warm soapy water, then rinse and dry. Check gaskets and seals for wear and replace if needed. Keeping the exterior free of coffee oils and dust helps maintain overall performance and hygiene.

The final check: after the rinse cycles, run one more full water-only cycle to verify there is no descaler residue. If a faint taste lingers, perform an additional rinse until the water runs clear. Reassemble all parts and resume normal operation.

Why does descaling matter? It prevents clogging that slows water flow, helps maintain stable temperatures, and reduces wear on the pump. A thorough descaling regime supports consistent extraction temperatures and a more uniform cup. For model-specific steps, consult your user manual or manufacturer support pages to capture precise instructions for your unit. You can refer to the manufacturer’s guidance at their support site for BUNN machines. If you want a practical walkthrough that mirrors this guide, look for model-specific pages that reflect your unit’s design.

Descale cadence: for homes with hard water or heavy usage, descale every one to three months; if your water is soft or usage is light, you can extend the interval. If you notice longer heats, slower pours, or dull flavor, schedule a descaling session. If performance doesn’t recover after descaling and rinsing, consider a professional service, though most issues are resolved by a thorough cleaning.

Within the broader care framework, descaling a BUNN coffee maker is a quiet, effective maintenance practice that preserves the machine’s reliability and your daily ritual. The chemistry is simple: minerals dissolve in the cleaning solution, water flows through the system, and rinsing removes residues so the next cup tastes as intended. The routine is both technical and practical, a stewardship of a common kitchen workhorse.

For further reading and up-to-date, model-specific guidance, consult official manuals and support resources from the manufacturer. If you want deeper insights or verification on any detail, you can visit the BUNN support page and related maintenance resources. External resources can complement the steps outlined here and help you maintain peak performance. For a concise hands-on guide that reflects practical steps, explore model-specific walkthroughs on the manufacturer site or trusted coffee education sites.

Preserving Peak Performance: The Essential Descale for a Commercial Drip Brewer

Descaling a high‑volume coffee maker is not just a housekeeping chore; it is a strategic maintenance practice that preserves the heart of the machine and the quality of every cup. In bustling cafes, hotels, or sizable office break rooms, mineral deposits from even clean municipal water can accumulate on the interior surfaces that heat, flow, and brew. Over time, these deposits, primarily calcium and magnesium, form scale that acts like a thorn in the side of a reliable brew. Scale insulates heating coils, narrows passageways, and creates hotspots that lead to uneven temperatures and erratic flow. The result is a brewed pot that lacks the consistency and warmth customers expect, and the machine itself bears a higher risk of overheating and, eventually, downtime. Regular descaling is the proactive countermeasure that ensures the brewer continues to operate at its designed capacity, producing coffee that tastes right at the same time of day, day after day, and year after year. When a business treats descaling as routine maintenance rather than a reactive fix, the payoff is measured not only in coffee quality but in the longevity of the equipment and the stability of service in peak hours.

To understand why descaling matters so much, it helps to picture the internal pathways that water travels as it moves from the reservoir through the plumbing and into the brew basket. In a high‑volume system, a small amount of mineral buildup can accumulate quickly on the heating element, along the piping, and around the brew group. Those deposits change how heat is transferred, which directly affects extraction temperature and contact time with the coffee. Slight shifts in temperature can swing the solubility balance of the grounds, muting aroma and altering flavor notes that your guests have come to expect. A well‑descaled machine, by contrast, maintains a steady heat profile, which translates into consistent brew strength and optimal extraction across multiple carafes.

Regular descaling also protects the physical integrity of the brewer. When mineral scale hardens around tight bends and joints, it can create resistance to flow and cause pump strain or motor load as the machine tries to push water through restricted passages. In the long run, that added stress can wear seals and gaskets or shorten the life of the heating element. For operators who run commercial brewers in shifts throughout the day, the cost of unexpected downtime or early component replacement easily exceeds the modest time invested in a disciplined descaling routine. The practice becomes part of a broader maintenance culture that values reliability, flavor integrity, and predictable performance.

The practical benefits of descaling extend beyond the machine itself into the cup. Scale can subtly alter the water’s contact with the coffee, influencing both aroma release and the perception of body. In markets where taste profiles are closely monitored, even a small deviation can be noticeable to trained staff and discerning guests. By removing scale, the brewer returns to its designed thermal efficiency, allowing the coffee to develop its intended bouquet and mouthfeel. The result is a more consistent flavor canvas across hours of service. In environments where multiple brew cycles are programmed for speed and repetition, such as banquet halls or busy offices, that consistency matters as much as speed or capacity. When you descale on a regular schedule, you’re not only maintaining the machine; you’re safeguarding the standard of quality that guests expect every time they walk up to the service station.

From a maintenance planning perspective, descaling also offers a predictable rhythm that aligns with staffing and facility operations. In commercial settings, the machine often remains in near‑constant use, and the water hardness of the local supply can influence how quickly scale forms. Descaling, therefore, should be integrated into a routine calendar rather than treated as an occasional deep clean. The general guidance is to schedule descaling every 1–3 months, with more frequent sessions in areas with very hard water or in facilities that operate at high throughput. This cadence keeps the system clean enough to deliver consistent results while preventing the scale from reaching a point where it requires aggressive cleaning or professional intervention. To tailor the schedule to a specific location, operators can test water hardness, observe any changes in heating time or brew temperature, and adjust the frequency accordingly.

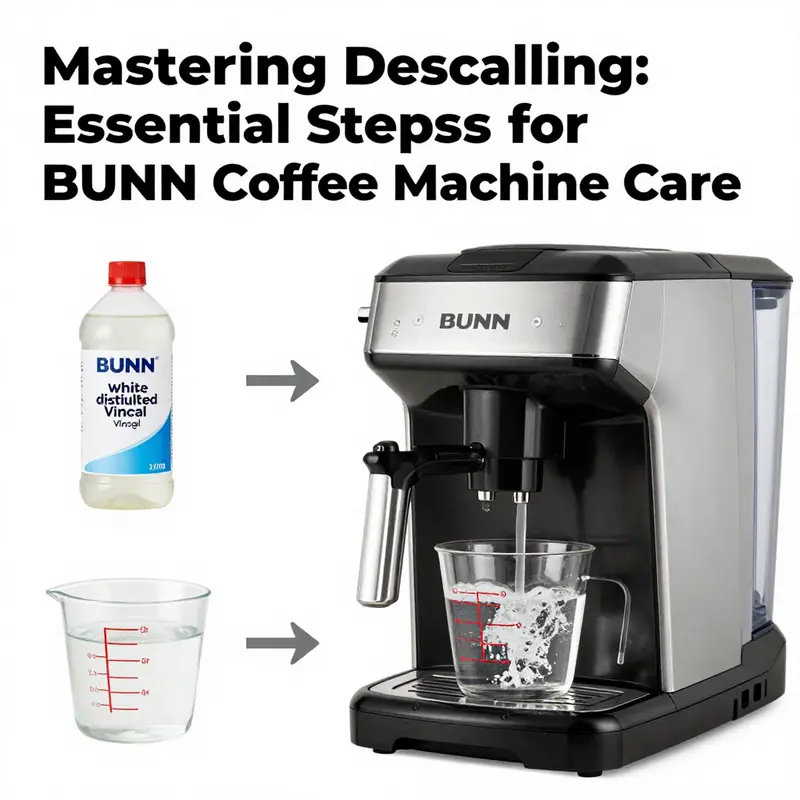

Descaling, at its core, relies on a simple, accessible chemistry—white distilled vinegar provides an effective, food‑safe acid that dissolves mineral scale without harsh abrasives. The practical method is straightforward. Begin by preparing a descaling solution by mixing white vinegar with water in a 1:1 ratio. The exact amount you run through the machine can vary with reservoir size and the scale’s extent, but a standard starting point is to introduce a measured volume that allows the solution to bathe the interior pathways. In many standard home and small commercial setups, pouring half a cup of vinegar into the reservoir and diluting it with an equal amount of water is a practical starting point. This approach forms a cleaning milieu that is potent enough to dislodge deposits yet gentle enough to protect seals and gaskets during the process. The exact volumes can be adjusted for larger reservoirs by maintaining the same dilution ratio and using proportionate quantities so the interior surfaces are exposed adequately without overwhelming the machine.

The next phase is the descaling cycle itself. Without coffee grounds in the basket, you initiate a brew cycle so the vinegar‑water solution runs through the entire internal plumbing, heating elements, and flow paths. This flush begins the process of loosening the mineral scale and carrying it out of the system. After the cycle completes, give the solution time to interact with the interior surfaces by letting it sit for a period—thirty minutes to an hour is common in many commercial routines. This soak acts as a mineral‑softening pause, letting the acid do its work while the machine remains safe from continuous heating. After the soak, run another full brew cycle using the same approach to maximize contact with the deposits and to push loosened scale toward the drain. A thorough descaling requires this two‑phase action: a flush to start the removal and a soak to maximize deposit dissolution, followed by another flush to begin the removal of loosened material.

Rinse, rinse, rinse. The crucial step after the descaling cycles is to remove any remaining vinegar and dissolved minerals from the interior. Run two to three complete cycles using clean water only. Each rinse is a chance to flush the system and to ensure that no residual vinegar remains that could interfere with coffee flavor in future brews. Skipping the thorough rinse is a frequent source of aftertaste complaints, especially in a high‑throughput environment where efficiency and taste are both central to service quality. While the interior is being rinsed, take a moment to inspect visible external components—the carafe, lid, and any removable parts—and wipe them down with warm, soapy water. Rinse thoroughly and dry before reassembly. A clean exterior not only looks professional but also reduces the chance that grime or soap residue enters the brew path during reassembly.

It is the combination of these interior cleanings and exterior hygiene that sustains overall performance. After completing the descaling and rinse cycles, many operators find it helpful to run an additional brew cycle with just water and no coffee to further flush the system, ensuring that any trace of mineral and vinegar residue has been eliminated from the heated passages. The goal is a clean slate, both in terms of taste and equipment integrity, so that the next pot of coffee can emerge with the proper temperature, aroma, and balance that customers have come to expect from the machine.

Incorporating descaling into a broader maintenance rhythm helps ensure that it remains routine rather than reactive. For professionals who manage multiple brewers, or for facilities with variable usage patterns, the descaling schedule becomes part of a standard operating procedure. The routine is more than a task; it is a safeguard that supports consistent brewing parameters, including water temperature and programmed brew times, which are critical in places where precise control over schedules is essential. When these parameters drift due to scale, the entire system can fall out of alignment with the programmed settings, producing inconsistent batches and undermining efficiency. Regular descaling keeps the programmable aspects of the brewer reliable, which in turn underpins downstream workflow and staffing expectations in any high‑volume setting.

For those seeking model‑specific nuance, it is wise to consult the manufacturer’s guidance and the relevant user manual. The descaling method described here aligns with widely accepted practice and is designed to be gentle enough for most commercial brewers while remaining robust enough to combat mineral buildup in busy environments. If you want to see a detailed, model‑level walkthrough, you can visit the detailed guide focused on cleaning a BUNN style brewer through the internal resource that consolidates practical steps and cautions. This guide, while concise, serves as a valuable complement to the general approach described here and can be accessed via the linked resource: how-to-clean-a-bunn-coffee-maker.

In addition to the procedural steps, a few practical considerations can help optimize results. First, use only clean water for the final rinsing cycles to avoid introducing any new mineral load or contaminants after the descaling. Second, avoid leaving the vinegar solution in contact with the components for excessive time; long exposure can, in rare cases, affect seals in older machines. Third, after descaling, recheck the machine’s temperature and confirm that the brew temperature aligns with the setpoints used for service. If a facility uses multiple brewers or has systems with programmable timing, it may be necessary to recalibrate the brew cycle sequences after a descaling event to ensure that the settings reflect the machine’s restored performance.

The maintenance cadence should be anchored by practical observation as well as the general guidance. In areas with exceptionally hard water, a shorter interval between descales is prudent, whereas in softer water regions, it may be perfectly reasonable to extend to the 2–3 month window. The guiding principle is to observe how quickly scale returns to the interior pathways and how noticeably performance shifts manifest in the brew output. When scale returns quickly, increase the frequency; when the system remains clean for longer periods, you can extend the interval slightly. This adaptive approach helps balance the time spent on maintenance with the value gained in performance and flavor consistency. For those implementing a daily or weekly program in large facilities, locking the descaling into a calendar reminder helps ensure it happens consistently and without neglect.

To maintain momentum, it can be helpful to keep a log of descaling events that notes the date, the interval since the last descale, water hardness level, and any observed changes in brew performance. This log becomes a practical reference for future scheduling and for communicating with maintenance staff or facility managers. The ultimate aim is to have a machine that remains reliable, efficient, and capable of delivering the same cherished cup of coffee during the busiest shifts as during the quietest ones. The discipline of descaling, properly implemented, is one of those durable routines that quietly supports your business by ensuring consistency, reducing the risk of unplanned downtime, and preserving the equipment you rely on to serve customers every day.

For those looking to connect this routine with broader resources, you can explore more guidance on maintenance from the manufacturer’s maintenance guide. This external resource provides up‑to‑date recommendations and model‑specific considerations that can complement the general approach described here. External resource: https://www.bunn.com/support/maintenance/.

Descale and Deliver: Troubleshooting the Descale Journey for a BUNN Coffee Maker

Scale is a quiet intruder in any hot-brew system. It settles on the heating element, clinging to pipes, and it thickens around the passages that carry water to your carafe. Over weeks and months, that mineral film can dull performance, slow heat, and subtly alter the taste of your coffee. Descaling isn’t a one-time chore; it’s a maintenance ritual that preserves efficiency, flavor clarity, and the overall health of the machine. When you start the descaling process with intention, you begin a process of restoration—one that not only cleans but also protects seals, valves, and gaskets from long-term wear. The practical, repeatable method that most home users trust begins with a simple pair of ingredients, a careful cycle, and a patient rinse. White distilled vinegar, diluted with water, has long been the go-to for many households. The acid in the mixture dissolves mineral deposits and helps loosen the stubborn scale that stubbornly adheres to the interior surfaces. Yet, as many coffee lovers discover, the path to a spotless machine isn’t a straight line. The journey features a series of common problems that can surface at different stages of the process. The key to overcoming these challenges is simple: understand what is likely to go wrong, and apply focused, model-safe solutions that keep the machine safe and the flavor stable. This chapter explores those typical hurdles, from incomplete scale removal and lingering odors to the risk of misread indicators like temperature drift or clogged lines. It also builds a practical framework for choosing descaling agents, balancing effectiveness with the integrity of rubber seals, plastic housings, and the heating element that powers every brew. In the end, the goal is not just to remove scale but to return your brewer to its original rhythm—hot, fast, and faithful to your chosen coffee profile. The heart of the process remains the same: circulate a cleaning solution through every reachable path inside the brewer, allow it to work, rinse thoroughly, and repeat when necessary. You will find that the details matter: the concentration of the solution, the duration of each soak, and the number of rinse cycles all influence the final outcome on taste and performance. A practical way to frame this is to imagine the descaling as a conversation between solution and mineral, where patience and precision are the translators that prevent miscommunication. When the message is clear, the machine breathes more freely, and the coffee flows with a steadier temperature, a more consistent pour, and a cleaner, brighter aroma that signals a job well done. The following reflections on common issues and their remedies aim to help you navigate the descaling journey with confidence, drawing on broadly recommended methods while staying mindful of model-specific guidelines. A balanced approach begins with preparation. Before you even pour the solution into the reservoir, ensure you’ve cleared the basket and lined up a clean carafe. The system will be circulating liquid through the same channels that normally deliver hot water to the brew basket, which is why a plan for the rinse phase is essential. If you prepare correctly, the descalers, whether a vinegar-water mix or a citric acid-based product, can do their work without compromising the integrity of seals or the pump. The goal is to remove mineral-scale buildup while preserving the life and performance of the internal components that make a great cup possible. For many users, the most straightforward approach uses equal parts white distilled vinegar and water. This dilution helps cushion seals and gaskets while still delivering the acidity needed to dissolve mineral deposits. The process is simple but requires attention to timing. First, the reservoir is filled with the vinegar-water solution, and a complete brew cycle is run without a coffee filter or grounds in the basket. The idea is to route liquid through the entire brewing pathway, from the reservoir to the showerhead to the carafe, with nothing getting in the way of the cleaning action. Once the cycle completes, the machine should rest with the solution inside for a period ranging from 30 minutes to an hour. That soaking interval is critical because it gives the acid enough time to interact with mineral deposits that may be clinging to the heating element and the metal surfaces around the tubes. After the soak, the cycle is run again to ensure thorough flushing of the interior. Then comes the rinsing phase, which is essential to avoid any lingering vinegar flavor in the coffee. Two to three additional cycles using clean water are described in most guidelines, and these cycles are where the final, neutral taste emerges. Once the interior is flushed, the exterior parts—the carafe, lid, and any removable components—should be cleaned with warm, soapy water, rinsed, and dried. In many homes, this simple routine becomes a reliable cadence that keeps a brewer singing at peak performance. Yet, as many readers discover, the straightforward vinegar method isn’t always the final answer. If scale buildup has reached a stubborn threshold or if the machine starts to emit a mild, vinegar-like odor in the coffee even after rinsing, many technicians and experienced users turn to a more robust descaling solution—one based on citric acid. Citric acid-based descalers are widely valued for their gentle yet resilient action. They dissolve mineral deposits without imposing harsh chemical stress on rubber gaskets or the plastic components that line the interior of a brewer. The principle remains the same: circulate the cleaner through the system, allow it to work, and rinse thoroughly with clean water. The difference lies in the chemistry. Citric acid often delivers a more neutral scent and flavor profile, which can be especially desirable if the acidity of the solution matters to the user or if the machine is sensitive to the more pungent odor that vinegar can produce. The recommended practice with these cleaners typically involves running the descaling solution through the brew cycle at least twice, with a soak of 15–30 minutes between cycles. As always, a rigorous rinse sequence follows, typically two to three cycles, to ensure all descaling residues are flushed away. If a user experiences lingering chemical notes, those additional rinses become more important, and the insistence on a thorough final rinse is a nonnegotiable step. The careful balance between effective cleaning and preserving component integrity is the other critical axis of this journey. The heating element is the heart of the machine’s performance. Scale acts as an insulating layer that impedes efficient heat transfer. When mineral deposits accumulate, preheat times stretch, and exit temperatures can drift away from the ideal range, which translates to a warmer carafe at the end of a slower sequence rather than a consistent, hot brew. This drift is especially noticeable in environments with particularly hard water or in households that rely on the brewer multiple times daily. Regular descaling, therefore, isn’t just about aroma and taste; it’s about energy efficiency and dependable operation. For those who notice slow heating or inconsistent temperatures, the prescription is straightforward: commit to descaling on a schedule aligned with water hardness and usage. In hard-water regions, more frequent descaling is prudent; in softer-water regions, the interval can be longer. A practical guideline is to aim for descaling every 3–6 months as a baseline, adjusting up when scale appears to accumulate rapidly or when preheat times elongate. Citric acid-based cleaners can be especially effective here because they provide a deeper clean that travels into microchannels that might be less accessible with a simple vinegar flush. It is also important to consider the potential for blockages formed by loose mineral chunks, especially after a heavy scaling incident. In some cases, the descaling solution can dislodge deposits that momentarily obstruct water lines or the pump. If you notice slow water flow or no water during a cycle after you begin the descaling process, don’t panic. Run additional plain-water rinses in short bursts to help clear the blockages. If the problem persists, consult the user manual that accompanied your machine or reach out to customer support. The performance of a coffee maker is a conversation among heat, water, and time. When one component deviates, the others respond. Descaling keeps this conversation on a healthy footing. The practical, experiential knowledge passed along by home brewers emphasizes a few consistent habits: use the correct concentration of cleaner, observe recommended soak times, and ensure a comprehensive rinse. The more carefully you follow these steps, the more likely you are to experience a faithful brew without flavor carryover from cleaning sessions. To support model-specific differences, many manufacturers maintain official manuals that provide precise directions for each unit’s heat cycle and internal routing. This is why, in addition to the general guidance described here, it can be wise to consult the official user manual for your exact model when available. The guidance includes cautions about not using abrasive cleaners, avoiding undiluted cleaners, and recognizing signs that internal gaskets or seals may be showing signs of wear. The overarching message is that descaling is not a perilous operation but a careful one. It rewards patience and methodical action. If you follow a disciplined process, you protect the machine and preserve the quality of every cup you brew. For readers seeking a concise, model-specific rundown, a reliable resource offers a step-by-step walkthrough that aligns with the method discussed above, highlighting its emphasis on thorough circulating cycles and repeat rinses. You can explore a detailed, model-specific guide here: how to clean a BUNN coffee maker. This internal reference complements the broader narrative by anchoring the practical steps to a trusted source while remaining easy to follow for home use. At the same time, it is important to acknowledge that fidelity to an official maintenance guide remains the best practice for any given unit. The official maintenance guide, which can be accessed through the manufacturer’s support portal, provides authoritative, model-aware instructions, and it reinforces the key cautions about chemical choice and rinse tempo. The balance of consumer experience with manufacturer guidance forms a coherent approach to descaling: begin with a simple, widely available solution, observe the internal flow, and adjust the technique to align with the machine’s temperament and the hardness of your water. The recommended cadence—seasoned by practical experience—accounts for those environmental variables that influence mineral deposition. Regular descaling—applied with care—rests at the core of reliable performance. It ensures that the machine’s heating element maintains efficient heat transfer and that the brew temperature remains stable, with less preheating lag and more predictability in extraction. In the long run, a well-maintained brewer yields better flavor clarity, a more consistent cup profile, and a generally smoother operation that reduces the chance of unplanned downtime. For those who include descaling as part of a routine, the process becomes nearly automatic: you measure, mix, and run; you soak; you rinse; you wipe down the exterior; and you confirm that the final rinse does not carry any residual scent. This approach aligns with the most robust advice from both home users and professionals who have tested descalers across various water conditions. It respects the integrity of the machine’s interior while delivering the clean, bright notes we expect from a well-maintained brew. Finally, the reader should remember that descaling is not a punishment for hard water but a life-preserving practice for the coffee maker. The mineral scale that forms over time is a symptom of use, not a failure of engineering. With the right care, a BUNN coffee maker can continue to deliver dependable performance for years. The objective is not to chase a perfect initial cleaning but to keep the system close to its original, efficient state. The process should be part of a broader routine of maintenance that includes cleaning the exterior regularly and inspecting removable parts for wear. If you approach descaling with this mindset, you’ll not only prevent leaks and overheating but also enjoy a cleaner, more vibrant cup with every brew. For a consolidated reference on model-specific steps and to verify any updates in the procedure, consult the official manual and support resources. External guidance can complement your practice, helping you tailor the cadence to your specific water quality and usage. External resource: BUNN Maintenance Guide – Official Website: https://www.bunn.com/support/manuals

Final thoughts

Regular descaling of your BUNN coffee maker is not just a maintenance task; it is a key factor in ensuring that your coffee remains fresh and flavorful, which is critical in a business environment. By following the steps outlined in this guide, you’ll minimize downtime, enhance the lifespan of your machine, and maintain high-quality coffee standards. Invest in this routine care, and make sure your customers continue to enjoy the perfect cup every time.