Maintaining a clean BUNN coffee pot is vital for any coffee-serving business. Regular cleaning not only prolongs the machine’s longevity but ensures that every cup of coffee served is free from unwanted residues and tastes fresh. In this guide, we’ll delve into effective daily cleaning steps, descaling techniques to prevent mineral buildup, and thorough internal maintenance to keep your coffee equipment performing at its best. Each chapter is designed to equip business owners with practical knowledge that not only improves coffee quality but also enhances overall customer satisfaction.

Daily Cleaning Rhythm for a BUNN Coffee Pot

The daily cleaning rhythm begins with recognizing that your coffee pot is more than a vessel; it’s a small, daily ally in flavor, aroma, and reliability. When you treat your BUNN with simple, consistent care, you’re not just removing yesterday’s oils, you’re helping every cup start fresh. The routine is quick and practical, designed to fit into your day rather than disrupt it.

First, attend to the carafe itself. After you’ve poured your last cup, rinse the interior with warm water and a small amount of mild dish soap. Use a soft cloth or non-abrasive sponge to lift oils that cling to the glass or stainless surface. If you notice a stubborn ring, a gentle scrub with a soft cloth and warm soap usually does the trick. For a touch of freshness, you can add a few drops of lemon juice to the wash water. The acidity helps cut through lingering oils and leaves a light, citrusy fragrance that dissipates as the pot dries. This tiny touch matters more than it seems because the carafe’s scent can influence the perception of your next brew. A clean carafe also helps in the evaluation of your coffee’s brightness and body because you’re not filtering through a stale baseline.

Next comes the lid and the seal. Detach the lid and the rubber seal ring near the spout, and wash these components with warm, soapy water. Rinse thoroughly to avoid any soap residue that could alter the taste of your coffee or cling to the seal. The seal ring deserves a quick inspection each day. If you notice any cracks, signs of aging, or deformation, replace it promptly to prevent leaks or seal issues that could compromise brewing consistency. Allow both pieces to air dry completely before reassembling. A tight seal ensures that the hot water is directed properly into the brew basket, which in turn preserves the intended extraction profile of your beans. The small moment spent on this check pays off in fewer leaks and smoother operation over time.

The exterior of the machine benefits from a brief, daily wipe-down as well. Use a slightly damp, soft cloth to wipe the control panel, the water tank, and the body. If you’re dealing with stubborn smudges or want a fresher scent, a few drops of lemon juice or a light, mild cleaner on the cloth can help deodorize and brighten the surface. The key is to avoid soaking any electrical components or allowing liquid to pool around switches or the base. After wiping, dry the surfaces with a clean cloth to prevent water spots and to maintain a tidy appearance. This daily attention not only keeps the machine looking new but also reinforces a habit of mind that translates into careful handling and longer life for the appliance.

If your model includes a hot water tank, you’ll want to refresh that space too on a daily basis, especially if the unit isn’t used continuously. Empty the hot water tank and rinse the inner walls with clean water. This step helps prevent mineral buildup from lingering water and keeps the tank fresh for the next use. If you know you won’t be drinking coffee for a while, it is wise to empty the tank entirely and allow it to air dry before storage. This minor routine reduces the chance of stale water stagnation and minimizes the risk of mineral deposits forming in the line that feeds the brew head. It also means that when you resume brewing, you’re starting with a clean, neutral water path rather than with yesterday’s residue interfering with flavor.

Beyond the daily ritual, it’s useful to keep an eye on long-term maintenance, particularly the need for a deeper clean every so often. Daily care is essential, but machines accumulate mineral deposits that can cloud flavor and impede performance. Manufacturer guidance generally recommends a more thorough descaling every 1–3 months, depending on water hardness and usage. This ongoing rhythm of everyday wipe-downs paired with periodic descaling creates a durable baseline for taste fidelity. When you do perform a deeper clean, you have a couple of reliable methods to choose from. The vinegar-and-water approach is a natural, accessible option that many users find effective. Mix half a cup white vinegar with half a cup distilled water in the reservoir, run the brew cycle halfway, unplug the machine, and let the solution sit for about two hours. This pause allows scale to loosen from interior surfaces. Then complete the brew cycle and discard the carafe contents. After that, rinse thoroughly by running 3–4 cycles with fresh cold water to remove any vinegar residue and odor. A final cycle with fresh water completes the process and prepares the machine for regular use. This method is compatible with many BUNN models, including popular lines, and is a reliable, affordable way to address mineral buildup without harsh chemicals.

If you are in an area with particularly hard water, or if you simply prefer a commercial descaler for peace of mind, you can opt for a descaling product designed for coffee machines. Use the descaler following the product’s instructions—normally, you pour a portion into the reservoir, fill with water, and run a brew cycle. After descaling, be sure to rinse with fresh water three to four times to remove any chemical residue and avoid altering the flavor profile of future brews. The important caveat is to avoid bleach or other aggressive chemicals that could damage internal components or contaminate the coffee. The goal is thorough cleansing without introducing harsh, unintended residues that can linger in tiny crevices or in the piping network.

There’s also value in paying attention to the spray head and spray nozzles during routine care. Carefully remove the brew basket and spray head according to your model’s manual, and inspect the tiny holes for mineral buildup. A toothpick or needle can gently clear obstructed holes, but you should avoid forcing debris that could damage the spray head. Wipe the external surface again with a damp cloth and mild soap, and use an interdental brush or a pipe cleaner for hard-to-reach areas. If your model includes a built-in descaling tool, it can be a more effective option than a makeshift toothpick for mineral removal. This small maintenance step helps ensure even extraction and a consistent spray pattern, which in turn sustains the steady flavor you expect from every pot.

When you complete a deeper clean—whether vinegar-based or descaler-based—be sure to flush the system thoroughly. Run 3–4 full cycles with fresh water to remove any cleaning solution from the internal pathways. This rinse is essential for preserving the integrity of the coffee’s taste, as any lingering cleaning agent can subtly mask delicate aromas or alter the perceived brightness of the cup. After this rinse, allow the machine to air-dry completely before storing or returning it to active use.

The daily cleaning rhythm doesn’t end with the immediate aftermath of a brew. If you’re not planning to use the machine for an extended period, you can adopt a simple storage routine that supports longevity. Make sure all components—the carafe, lid, seal, spray head, and any removable piping—are thoroughly clean and dry before storage. Store the unit in a cool, dry place away from direct sunlight, which can degrade seals and plastics over time. A consistent, dry environment reduces the risk of moisture-related damage and keeps plastics from becoming brittle. In this way, your daily care becomes a keeper of long-term health for the machine, rather than a set of isolated tasks.

This approach to daily care also reinforces a broader respect for flavor integrity. When you wash away yesterday’s oils and mineral films promptly, you maintain the coffee’s natural sweetness, acidity, and body. You reduce the chance of off-flavors that linger in the pot or in the machine’s internal conduits. You also create a predictable brewing environment where the brew head, the water path, and the carafe all operate with consistent precision. Over time, this translates into a more reliable extraction profile: cleaner, brighter cups that taste more like the beans you chose and less like the weathered residues of days gone by. The benefits compound: fewer cleaning emergencies, quicker brewing, and a more satisfying daily ritual.

For readers seeking a concise, model-specific path, a broader guide to BUNN care can provide further nuance without complicating the routine described here. For a broader guide to maintenance that digs into model-specific guidance, consider the following resource: How to Clean a Bunn Coffee Maker. This internal reference complements the steps outlined above by offering practical tips and model-focused considerations you might encounter as you navigate alternative hardware configurations. It’s not a replacement for your user manual, but it can broaden your understanding of how daily cleaning intersects with periodic maintenance across different BUNN lines. If you value precise specifications, you can always cross-check with the official manuals that accompany your unit to ensure that any product-specific cautions are observed and aligned with warranty guidelines.

In the end, the daily cleaning rhythm is not an ordeal but a habit. When you embrace a short, repeatable routine, you protect the integrity of your coffee, safeguard the equipment, and enhance the consistency you rely on for your morning cup. You’ll notice that the routine becomes almost automatic: a quick rinse, a gentle wipe, a light check of the seal, and a final dry. The ritual rewards you with cleaner surfaces, a fresher aroma, and a cup that tastes closer to the origin of the beans. As with any practice that touches hot water, detergents, and metal, a mindful approach matters. Gentle soaps, warm water, and patient drying create a loop that sustains the machine’s performance and the quality of your daily brew.

External resource: Official BUNN manuals can be found at https://www.bunn.com/support/manuals/.

Descaling with Precision: Mastering Mineral Removal in a BUNN Coffee Pot

Descaling with precision is the quiet work that keeps a BUNN coffee pot brewing at peak performance. It’s not just about removing stains; it’s about freeing narrow passages from mineral crusts that form when hard water lingers in the machine’s heart. Over time, calcium and magnesium compounds accumulate in the reservoir, the spray head, and the tubes that carry hot water to the carafe. The effect is gradual: slower brewing, uneven extraction, and, occasionally, off flavors that whisper of the mineral depths. Descaling, then, becomes a ritual of restoration, a careful reawakening of the machine’s efficiency and the purity of every pot that follows. As you approach this routine, you’ll discover that the process can be straightforward, repeatable, and surprisingly satisfying once you see the same clean water return to the surface during rinses and the spray head holes gleam again. This chapter unfolds descaling as a cohesive practice, weaving together the most reliable methods with model-aware guidance, practical safeguards, and a seamless flow from preparation to finish that keeps the machine ready for the next brew without drama or guesswork. If you want a concise, step-by-step reminder that fits into a busy morning, you’ll find a clear path here, anchored by the strongest recommendations from official guidelines and long-standing best practices. And if you ever want to see a real-world, model-specific walkthrough, you can explore the dedicated guide linked here: how to clean a bunn coffee maker. While you read, keep in mind that the goal is to remove mineral buildup thoroughly while preserving the integrity of gaskets, seals, and the spray system. A careful hand during disassembly, coupled with patient rinsing, helps extend the life of the machine and the flavor of every cup.

The most widely used descaling approach begins with a simple, proven solution: vinegar and water. The logic is straightforward. White vinegar disrupts mineral bonds and loosens the scale that clings to internal surfaces. For a 10-cup speed brew or platinum series, the recommended ratio is one part white vinegar to one part water. In practice, that means pouring an equal measure of distilled white vinegar and water into the reservoir, enough to fill the machine’s standard operating level. For the smaller models, you adjust the ratio to balance effectiveness with gentleness on the hardware—typically a 1:1 mix still works, but you might use a slightly smaller quantity if the reservoir is compact. If you operate a VPR commercial series unit, you’ll find the same 1:1 ratio effective, with the caveat that you should allow the machine to cool before starting the cycle; the process is the same, but safety and timing become more important in commercial-scale use.

Begin the descaling cycle as you would a normal brew. Start the cycle and watch as the solution begins to travel through the system. When half of the solution has drawn into the carafe, the key moment arrives: unplug the machine and let the liquid sit for at least two hours. This soaking period gives the vinegar time to dissolve mineral deposits that have formed a stubborn crust around the spray head and in the narrow passages. After the soak, resume and complete the brew cycle, then discard the carafe contents. Rinse thoroughly by repeating the brew with fresh cold water three to four times. The goal is to flush every corner of the system, removing both the vinegar itself and any loosened mineral particles until the carafe stops smelling of vinegar and the water runs clear. It’s a rinse-and-flush ritual that restores flow and aroma, letting the coffee that follows taste as close as possible to the original, unblemished profile. This method is versatile enough to handle most BUNN models, including the VPR-APS and Speed Brewer line, and the basic speed brewers alike, which makes it a reliable first approach for many homes and small offices.

If you’d prefer alternatives to the vinegar route—whether due to a sensitive palate, a preference for milder cleaners, or concerns about the smell lingering in your kitchen—there are other effective descalers you can use. Baking soda, for example, offers a gentler yet effective option. The recommended mix is one cup of warm water combined with about 0.4 cups of baking soda. Pour this solution into the reservoir and run a full brew cycle as described for the vinegar method. The baking soda does not have the same strong odor as vinegar, and many users find it leaves the machine feeling fresh without any residual scent. It’s a viable choice when mineral buildup is moderate or when you want a softer approach to cleaning. Lemon juice provides another natural acid that can dissolve scale while imparting a pleasant citrus aroma. Combine 0.5 cups of fresh lemon juice with 0.5 cups of water, pour into the reservoir, and run the cycle in the same two-stage pattern: draw half the solution, pause with the machine unplugged for the two-hour soak, then complete the brew and rinse thoroughly. The lemon route is particularly appealing if you enjoy a lemony note accompanying your coffee routine, and it can be especially effective in tandem with a robust rinse. Both baking soda and lemon juice are gentle alternatives that complement the vinegar method, offering flexibility for households with different sensitivities, tastes, and tolerance for odors.

For those who prefer a commercial descaler—especially in regions with very hard water—there are products designed specifically for coffee makers that are formulated to be food-safe and effective. When using a commercial descaler, the instructions typically require filling the reservoir halfway with the descaling solution and topping it up with water to the full reservoir level before starting a full brew cycle. After completing the cycle, you rinse with fresh water several times to ensure any chemical residue is removed. The key caution with any chemical descaler is to use only products that are labeled as coffee-machine safe and to follow the manufacturer’s directions to the letter. Bleach and other harsh chemical agents must be avoided, as they can damage internal components and leave residues that could contaminate future brews. This approach is particularly appealing in environments with stubborn mineral buildup, or where water hardness is especially intense. In such cases, following the product’s instructions closely ensures the descaler works effectively while maintaining the machine’s longevity and your safety.

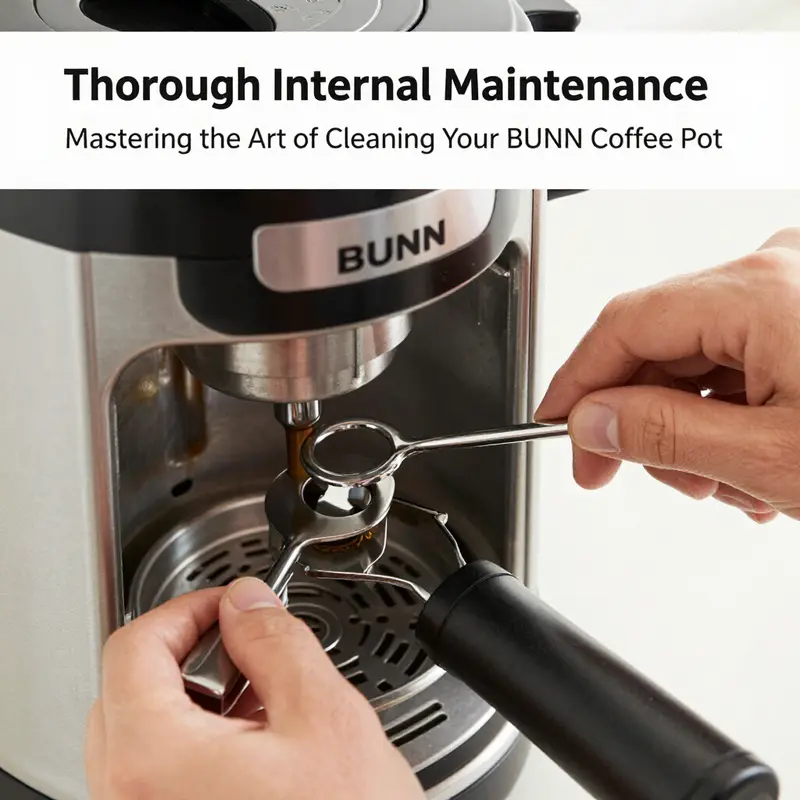

Beyond the primary descaling step, attention to the internal components of the machine matters just as much as the cleaning solution you choose. A dedicated descaling protocol calls for clearing the spray head to ensure every orifice remains open. Remove the brew basket and carefully unscrew the spray head. Use a toothpick or a fine needle to gently dislodge mineral deposits that may be clogging the tiny holes. Wipe the exterior with a damp cloth and a mild dish soap to remove any film from the cleaning process, then attend to hard-to-reach places with a pipe cleaner or interdental brush. If your model includes a purpose-built descaling tool, prefer that tool for better results in this step, as it is designed to fit the parts precisely and minimize risk of damage. Cleaning the spray tube itself is equally important. Insert a pipe cleaner or a descaling brush into the tube where the spray head attaches, rotate, and move it back and forth to scrub away residue. Check bypass lines or connectors if accessible and give them a quick pass to ensure nothing remains sticky or clogged. This hands-on cleaning of the spray head and spray tube helps guarantee an even spray pattern during the next brew, which in turn contributes to consistent extraction and better-tasting coffee.

In many cases, the manufacturer offers specialized tools for descaling or cleaning beyond the basic implements. If you have one of these tools, use it in place of a generic pipe cleaner for a better fit and more thorough cleaning. If you need replacements or guidance, you can call customer service for model-specific assistance and to order the appropriate descaling tools. The numbers vary by region, but in the United States and Canada, the support channels are clear and designed to help you get the right parts for your exact model. Access to the right tool can make a meaningful difference in how easily you can maintain the machine over time.

Once the chosen descaling method has been applied and the internal components have been cleaned, the final stage is a comprehensive rinse. Refill the reservoir with fresh, cold water and run three to four complete brew cycles, discarding the contents of each carafe. This series of rinses is essential to remove any lingering cleaning solution and dissolved minerals, as well as to re-establish a clean, neutral baseline for the next pot. After the final rinse, allow the machine to air-dry completely before storing or using again. Air-drying helps ensure that no damp environments linger inside the hardware, which could promote mold or odors during storage. In most households, this step is quick and unobtrusive, requiring only a little patience while chores through the kitchen are completed.

If you anticipate a period of extended non-use, prepare the machine for long-term storage. Ensure that every component is thoroughly cleaned and completely dry, including the carafe and any removable parts. Store the machine in a cool, dry place away from direct sunlight to preserve materials and prevent warping or degradation. A dry environment also minimizes the risk of corrosion in any metal fittings and helps maintain the integrity of seals and gaskets for the next round of use. This forward-looking step keeps your machine in top shape, ready to deliver consistent coffee when you return.

The descaling process, when done with care, yields more than just clean metal and clear water. It restores the machine’s ability to heat water evenly, pushes cleaner water through the spray head, and helps produce a more uniform extraction that reveals clearer aromatics and a truer flavor profile in the cup. There is a tangible sense of renewal as you watch the water flow with less resistance and the carafe fill more quickly because deposits have been removed from the passages that govern flow. The senses respond to this renewal: the aroma of brewed coffee feels more vibrant, and the first cup after a descaling cycle tends to taste closer to the intention of the original roast, unmasked by mineral tang. With continued care—regular descaling aligned with your water hardness, periodic checks of gaskets and seals, and mindful rinsing—the machine remains a faithful workhorse that can serve you well for years.

To keep the flow of trustworthy guidance intact, it’s helpful to remember that model-specific nuances exist. While the ratios and general steps often translate well across most machines, some models may require minor adjustments. That is where consulting the official user manual becomes valuable. It offers model-aware instructions, safety cautions, and any special steps designed for your unit. If you want a deeper dive tailored to your exact machine, you can consult the guide linked earlier: how to clean a bunn coffee maker. This reference can guide you through any idiosyncrasies your model might present, ensuring you never guess when a warning light or unusual aroma appears during a descaling cycle.

As you work through the descaling routine, keep a few practical reminders in mind. Always unplug the unit before disassembling any parts to avoid the risk of electric shock or unintended activation. Allow the machine to cool if it has heated up during a cycle before handling spray heads or tubing. Avoid splashing water or cleaner on electrical components, and use mild dish soap for exterior surfaces to preserve the finish. If a particular step feels uncertain, pause and refer back to the manual rather than forcing a process. The goal is not to rush a descaling cycle but to complete it with careful attention to each component so that nothing is left behind. Even a small missed spot can show up as a missed pulse of flavor in the next brew, so patience is a virtue in this work.

In practice, the descaling process becomes a predictable rhythm: mix or prepare the chosen solution, start the cycle, use the two-hour soak when required, complete the brew, rinse thoroughly, clean sprayed heads and tubes, perform a final rinse, and then dry and store. The rhythm is not merely procedural; it’s a ritual of upkeep that pays dividends in flavor, efficiency, and reliability. You’ll notice the improvements in the machine’s responsiveness and the consistency of your coffee, especially as mineral buildup becomes less of an obstacle. And because mineral deposits can form more quickly in areas with exceptionally hard water, you may find yourself descaling more often in certain seasons or neighborhoods. The key is to monitor performance and adjust the cadence to your water conditions, not to wait for a noticeable decline before taking action.

If you’re curious about further refinements or you want to explore a broader range of techniques, there is value in cross-referencing reliable sources and manuals. A structured, model-aware approach can accommodate both the broad guidelines and the small adjustments that best fit your equipment. Whether you are maintaining a residential brewmaster or a busy office setup, descaling with intention remains the best way to sustain a clean system and a satisfying cup. In the end, descaling is less about chemistry and more about stewardship: you care for the machine, and it returns that care in every cup you pour. The result is a reliably bright, clean-tasting coffee that speaks to the care you invest in maintenance, year after year.

For readers who want to see the practical steps in a concise, model-specific format, you can follow the dedicated instruction page linked above. The guidance there aligns with the core principles described here, while providing checklists, model-specific diagrams, and troubleshooting hints should you encounter a stubborn buildup or an unexpected scent during or after a descaling cycle. This alignment between general best practices and model-focused advice ensures that you can approach descaling with confidence, no matter your setup.

External resource:

https://www.bunn.com/support/manuals/

Delving Beneath the Surface: Thorough Internal Maintenance for a Clean BUNN Coffee Pot

When you reach for a cup of coffee, the first aroma you notice often comes from the brew you just made rather than the machine you used. But the most important work happens well beyond the visible surfaces. A BUNN coffee pot, celebrated for speed and consistency, relies on a network of internal paths and a boiler that must stay free of mineral scale and gunk to deliver hot, flavorful coffee every time. Thorough internal maintenance is not a luxury; it is a practical discipline that protects heat transfer, preserves the integrity of gaskets and seals, and keeps the machine operating with the same brisk efficiency it had on the day you bought it. The aim is simple and enduring: remove scale, cleanse the plumbing, and reassemble with care so the system can once again perform as designed. This approach blends the official guidance with a careful, hands on understanding of how the internal components work together. It is a process that prizes patience over force, precision over shortcuts, and it is most effective when viewed as part of an ongoing maintenance habit rather than a one off deep clean. For those who want a compact reminder of the basics while you read, consider this integrated perspective as a continuation of the routine you already perform after each brew, an extension that protects the machine from the inside out and keeps the flavor profile of your coffee consistent across months and even years of use. If you want a concise companion guide to the basics, you can follow a related short piece here How to clean a BUNN coffee maker. It offers a streamlined overview that pairs nicely with the deeper internal work described here and helps you align daily care with periodic maintenance so the machine remains reliable and efficient. To complete the circle, keep in mind that model specifics will always matter; when in doubt, consult the official manuals that accompany your BUNN unit and use them as your primary reference for disassembly, parts compatibility, and any warranty considerations. The journey into the machine is as much about respect for its engineering as it is about the ritual of making coffee that tastes right every time. Now let us move through the internal maintenance sequence with a focus on what matters most inside the shell: mineral deposits, residue, and the clean pathways that let hot water travel where it should without resistance or delay.

Begin with a clear understanding of why the inside matters. Mineral-rich water, especially in hard water regions, leaves scale on the boiler and in the narrow tubes that feed the spray head. That scale acts like a tiny insulator and a traffic jam at the same time: it slows heating, reduces water flow, and can alter the temperature profile of the brew. Because the boiler and its immediate plumbing are sealed parts of the system, they respond best to a controlled, deliberate cleaning cycle. The goal is not only to dissolve scale but to flush out residues that accumulate over time, including coffee oils that cling to the inner walls and micro fragments that drift through the brew head. A disciplined approach to cleaning respects the design intent of the machine, preserves the integrity of seals and gaskets, and minimizes the risk of chemical residues in the brew. It also aligns with warranty expectations, since using manufacturer approved methods reduces the chance of inadvertent damage during disassembly or descaling. The steps that follow read like a conversation between you and the machine: you initiate the descaling flow, you pause to soak and soften deposits, you reassemble with care, and you flush the system until only clean water remains in the carafe. The result is a pot that heats evenly, pours with minimal effort, and delivers a clean taste that reflects your attention to the machine’s inner life as much as the beans you grind and the water you pour.

The first decision in internal maintenance is choosing the right descaling agent. The guidance you rely on emphasizes the difference between a purpose built descaler and household options. A commercial descaler designed for coffee equipment is preferred for its formulation, which targets mineral build up while preserving the rubber and metal components that are in regular contact with water and cleaning solution. If you opt for a household alternative, white vinegar is a workable option in moderation but should not be used too frequently. Prolonged or repeated exposure to acidic solutions can wear down rubber seals and gaskets over time, which in turn can lead to leaks or changes in brew temperature. The practical approach is to select a descaler that matches your machine’s scale level and model, then follow the manufacturer’s recommended dilution and soak times. For a ten cup model type mentioned in official references, the practice is to mix a full descaler with the water as instructed, but in general the principle holds: a well balanced solution, permeating the internal channels, allows scale to dissolve without stressing the polymer components that seal the hot water pathways.

With the cleaning solution prepared, the descaling cycle becomes a careful dance between flow and pause. You start the brew cycle with the carafe in place but with the machine empty of freshly brewed coffee, and you allow the solution to travel through the brew head and into the carafe until the reservoir is emptied. The key move is to stop the cycle before it finishes, unplug the machine, and let the solution sit inside the system for an extended soak. The rationale is to give the cleaner time to penetrate the boiler, the spray head, and the passages feeding the shower screen, loosening mineral deposits that resist simple flushes. The soaking window, ideally at least two hours and sometimes longer, is a moment of stillness that pays off when you return to rinse. The next phase is a full cycle using only fresh water to carry away the descaler and any dissolved minerals. A sequence of three to four complete cycles is typical, each one rinsing deeper than the last and leaving the system in a neutral state ready for the final rinse with clean water. By the end of this flush, any lingering scent or taste of the cleaning solution should be gone, replaced by the neutral profile of fresh water and the expected temperature of the brew. If the machine is particularly scale laden, a longer soak time or a second round of descaling may be prudent, but the principle remains steady: thorough flushing ensures no chemical residue remains that could affect the next pot of coffee.

The moment of physical inspection follows the chemical work. It is time to turn attention to the brew head and the shower screen. These components are the last mile between the water in the reservoir and the coffee grounds that shape the brew’s flavor. The shower screen is a delicate perforated plate that distributes water evenly over the coffee and helps maximize extraction. Scale and mineral deposits here can create uneven spray patterns, channeling, or the buildup that reduces the disc’s permeability. You remove the brew head assembly and the shower screen according to model specific procedures and prepare a soft brush for careful cleaning. A small soft bristled brush, such as an old toothbrush, can be your best ally for dislodging stubborn scale around the tiny holes in the screen. For stubborn deposits, a thin wire or pipe cleaner can be used to clear the holes, but you should exercise gentle control to avoid bending or distorting the screen. External cleaning of the brew head area with a damp cloth and mild dish soap helps remove any film that the descaler may leave on the surface. If your model offers a specialized descaling tool, this can improve the precision of deposits removal around the minute apertures. The goal is to restore the spray head to its original condition so that the water can pass through as evenly as possible, a prerequisite for consistent extraction in subsequent brews. From there, you reassemble the brew head, ensuring the shower screen seats properly, and you check for any residue along the edge where the assembly meets the body of the machine. This is the moment to reflect on the notion that internal maintenance is a routine, not an isolated event. The more consistently you perform these steps, the less scale will accumulate in the future and the easier future cleanings will be.

The internal tubes and passageways deserve their own careful attention. The spray tube and the bypass lines feed hot water through the system in a precise choreography that determines where the water contacts the coffee and how evenly heat is applied. A flexible cleaning brush or a specialized descaling tool can be inserted into the spray tube to scrub away residue, moving it back and forth to clear the path. In some models the bypass lines may be accessible for cleaning; if so, you should inspect them for any kinks or blockages and address them with the same gentle, methodical approach you used on the spray head. This step completes the core interior maintenance: cleaning the channels through which water travels from reservoir to brew head and on to the carafe. The aim is to restore free flow and prevent any micro obstructions that could compromise performance. After cleaning, you rinse all parts thoroughly under clean water before reassembly. The reassembly step is not merely about getting the machine back together; it is about re-creating the original alignment that ensures reliable operation. Make sure all components are dry before you reinsert them, especially any seals or gaskets that can swell or warp if left damp. This stage, though technical, is a natural extension of the earlier descaling work and a sign that the machine is returning to its peak operating condition.

Reassembly paves the way for the final phase: the flush and test. Once the brew head and screens are tightened and the reservoir is filled with fresh water, run a full pot to confirm that the machine flows freely and heats evenly. The first few cups after such an internal maintenance routine may carry a faint taste of the cleaning solution, a reminder that flavor takes a moment to recover from the internal treatment. It is wise to discard these initial cups and then resume normal usage. If a detectable odor or taste lingers beyond a couple of cycles, you may need to repeat the flush sequence, ensuring that every nook where solution might reside is flushed clean. This is the practical payoff of the internal maintenance program: a consistent flavor profile, reliable heating performance, and a machine that feels as responsive as it did when new. In addition, you preserve the machine’s warranty by adhering to these guidelines, including the use of appropriate descalers and following model specific instructions carefully. The discipline of internal maintenance translates into better cup quality and a longer life for the appliance, reducing the odds of unexpected downtime and the cost of premature replacement.

As you consider the long view, internal maintenance is part of a broader care routine that includes extra attention to the carafe, the exterior, and the daily duties you perform after each brew. The carafe deserves a warm rinse with mild soap and water, followed by thorough drying to prevent any odor development. Wipe down the exterior with a damp cloth and mild soap, taking care not to spray water into electrical components. The aim is to keep the machine presentable and hygienic while safeguarding the internal components from exposure to moisture and cleaning agents beyond what is necessary for proper maintenance.

Finally, if the machine will be stored for an extended period, prepare it by ensuring all parts are completely clean and completely dry, with the carafe removed for storage to prevent any moisture buildup or mold development. Store in a cool, dry place away from sunlight to protect plastic and rubber parts from UV degradation. This long term storage mindset helps ensure that when you pull the unit out of storage, it is ready for a fresh cycle without the need for an immediate deep clean. The conversation between you and the machine remains ongoing, and the more you attend to its inner life over time, the better your coffee experience will be.

To reinforce the guidance you have absorbed here, consider returning to this topic whenever you notice a dip in performance or a change in flavor. Internal maintenance is about listening to subtle cues—the way the water flows, the sound of the boiler heating, the presence or absence of a metallic tang in the cup—and acting promptly before those cues become more serious issues. It is a practical habit, not a ritual that must be performed with the clock running. In the end, a clean interior keeps the machine honest about its role in your daily ritual and helps you savor the moment when you pour a cup that tastes exactly as you want it to taste. The internal maintenance described here complements the daily care and the periodic descaling that keep your coffee experience steady, reliable, and free from unnecessary interruptions. It is the quiet work behind the scenes that allows the bright, brisk performance you expect from a well built coffee maker to continue for years.

If you want more practical context that connects this depth of maintenance with everyday routines, see the guide mentioned earlier for a concise overview and quick reminders. The deeper dive into internal maintenance complements that overview by giving you the full sense of where the work happens inside the machine and why the sequence matters for performance and flavor. For model specific disassembly instructions, always refer to the official manuals, which provide diagrams and step by step directions tailored to your exact unit. The combination of disciplined maintenance, careful cleaning, and accurate reassembly ensures your BUNN coffee pot remains not only functional but capable of delivering the same hallmark speed and flavor you expect from a trusted workhorse in your kitchen. External references and model specific documentation can be found at the official support resources, including the manuals that accompany your machine. Maintaining the machine inside and out is an investment in your coffee experience, and the rewards come cup after cup, brew after brew, as the machine continues to work with dependable consistency and the flavor profile you prize. For model specific instructions and the most up to date guidance, refer to the official manuals. External reference: https://www.bunn.com/support/manuals/

External resource note: In addition to model specific instructions, ongoing maintenance benefits from keeping abreast of official recommendations for descalers and safe cleaning practices as published by the manufacturer. This ensures you remain aligned with product design intent while protecting your investment. You can explore more about general care and maintenance guidelines in the broader support resources provided by the manufacturer, which cover compatibility with various accessories and replacement parts as your unit ages. The path to a consistently clean pot is a path you walk with care, curiosity, and respect for the precision engineering that makes the everyday ritual of coffee possible.

Final thoughts

Ensuring that your BUNN coffee pot remains clean and well-maintained isn’t just about aesthetics; it’s essential for crafting the best coffee possible and providing outstanding service to your customers. By following the outlined daily cleaning steps, descaling techniques, and conducting thorough internal maintenance, you can optimize both the longevity of your coffee maker and the quality of your brews. Implementing these practices will not only enhance your operational efficiency but also elevate your customers’ coffee experience, allowing your business to thrive.