Maintaining a pristine BUNN coffee pot is vital for business owners who rely on coffee to fuel their operation. Accumulated scale, residue, and stains can not only compromise the taste of your coffee but also affect the longevity of your equipment. By adopting a diligent cleaning routine, you not only uphold coffee quality but also enhance the performance and life span of your brewing system. This guide delves into essential cleaning techniques for both internal and external components of the BUNN coffee pot, along with best maintenance practices to keep your machine running smoothly. With deliberate care and regular attention, your BUNN coffee machine can continue serving delicious brews day in and day out.

From Scale to Sparkle: Mastering the Internal Clean of a Commercial BUNN Coffee Pot

The daily rush of a busy commercial coffee program tests every inch of a brewer’s reliability. In the high-traffic world where a BUNN coffee pot lives, mineral buildup and oil residues don’t announce their presence with fanfare; they accumulate slowly, stubbornly, and then suddenly you notice a subtle shift in flavor, a slower pour, or a short-lived hiss when the machine heats. Cleanliness is not merely about aesthetics or compliance with a checklist. It is about preserving the very heart of the machine—the internal passages, the boiler, the spray system, and the tubes that carry hot water to the shower head. When scale, oils, and micro deposits are allowed to cling to those surfaces, they constrict flow, insulate heat, and create flavors that drift away from the intended profile of your blend. A methodical internal clean is, in practical terms, a preventive maintenance ritual that protects your investment, sustains consistent extraction, and keeps the workflow smooth during peak service. The approach described here is drawn from official guidelines and seasoned practice in busy settings, where a disciplined routine translates directly into better coffee, fewer service interruptions, and a longer life for the machine itself.

Begin with a precise mindset: you are not simply removing visible grime. You are inviting fresh water to pass a clean, open corridor from the reservoir, through the boiler, and down to the spray head. The most common culprit inside is mineral scale, a crystalline residue that forms where hard water cycles through hot surfaces. Scale acts like a miniature battery, drawing heat away from the water and creating pockets where cleaning agents struggle to circulate. In a commercial context, even a modest buildup can become a bottleneck—reducing steam generation, altering the timing of extraction, and changing the steeped temperature inside the brew cycle. The internal clean is the antidote to this drift. It aligns the machine’s thermal performance with its design, enabling predictable extraction curves and, ultimately, consistent taste across the day’s batches.

The first move is to prepare a solution that aggressively targets scale but remains safe for metal, seals, and gaskets. The most widely recommended approach is a clean, balanced mixture of distilled white vinegar and water in a 50/50 ratio. This isn’t a casual rinse; it is a working descaler designed to loosen the stubborn bond between mineral crystals and the metal passages that carry hot water. For larger units—the kind that fill a carafe on a high-volume line—the recipe scales up in a straightforward way: two cups of vinegar to two cups of water will fill the reservoir proportionally for a 10-cup Speed Brewer or Platinum Thermal brewer. If you operate a smaller model, the same principle applies; reduce the quantities in the same proportion so that the concentration remains effective but not overpowering. The important detail is to ensure the mixture actually flows through the system and coats the internal surfaces evenly. If vinegar isn’t part of your plan for any reason, there are credible alternatives with similar descaling power: a warm mixture of 0.4 cups baking soda dissolved in 1 cup warm water, or a 1:1 blend of lemon juice and water. Commercial descaling agents are another valid choice, provided you follow the product instructions to the letter. The goal is not to create a chemical storm but to deliver a controlled, effective treatment that dissolves scale without risking damage to seals or circuitry.

With the cleaning solution prepared, you return the brewing funnel to its seat and power the machine. The next phase is a deliberate, controlled exposure of the internal pathways. You start the machine as if you were brewing the regular cycle. The control system will draw the cleaning solution into the carafe, and you watch for a moment when approximately half of the solution has moved through the boiler and into the carafe. At that precise moment, you unplug the brewer. This is not a hesitation for drama; it is a calculated pause that lets the descaling solution soak inside the boiler, along the spray tube, and around the internal fittings. The soak period is critical: at least two hours is recommended to allow the solution to interact with mineral deposits, loosening their grip on the metal walls. In busy environments, this is the moment to step back and take a quick inventory of other tasks—calibrating a grinder, cleaning a workstation, or restocking filters—so the hold time becomes an efficient pause rather than downtime. When the two hours have elapsed, the internal surfaces have been softened by the solution, and the stage is set for rinsing and restoration.

Reestablishing access to the internal components begins with the shower head, the hub that distributes water evenly across the coffee bed. The shower head, sometimes integrated with a small connector inside the funnel, is notorious for developing mineral crusts in the tiny orifices that spray water onto the grounds. Carefully detach the shower head from the brewing funnel, using a gentle force so as not to strip threads or damage gaskets. A toothpick or a soft brush works well to agitate and clear the mineral deposits from the narrow holes. After removing deposits, wipe the exterior with a damp cloth—mild, fragrance-free dish soap is perfectly acceptable for final residue removal. For especially tight spots around the connection, a flexible pipe cleaner can reach into nooks that the fingertip cannot. The underlying philosophy is to restore a clean, unimpeded spray path so water can meet coffee grounds evenly and consistently during the subsequent cycles.

The next component under scrutiny is the spray tube itself—the conduit that carries the heated liquid from the boiler to the shower head. A block in this tube can cause uneven pour patterns and under-extracted coffee. Insert a descaling tool or a pipe cleaner brush into the spray tube and begin a coordinated back-and-forth motion. The goal is to scrub the interior in a way that dislodges any stubborn scale or oil residue clinging to the walls. If your machine shipped with a dedicated cleaning rod or a specialized tube brush, use that tool in place of a general-purpose brush; the design of these tools tends to align with the dimensions of the BUNN plumbing, offering a more thorough clean with less risk of internal damage. Don’t neglect the bypass fittings or any additional tubes that are connected to the spray tube; a comprehensive approach prevents pockets of grime from hiding in narrow pathways. Once you have worked the interior, reassemble the shower head and return the funnel to its original seat, preparing for the final rinse phase.

Rinsing is where intention meets repetition. Reconnect the brewing funnel and plug the machine back in. Turn the unit on and allow it to complete a full brew cycle using only fresh water. When the cycle finishes, discard the water from the carafe. Refill the reservoir with fresh cold water and run another full brew cycle, discarding the water again. The rinsing process should be repeated three to four times, a deliberate sequence designed to flush out any remaining cleaning solution and to remove the telltale vinegary aroma that lingers when scale sits in contact with metal for an extended period. The objective is not merely to remove cleaner; it is to ensure the machine is truly ready for regular operation and that no taste of the descaler migrates into the coffee. In practice, you want the rinse water to emerge free of any residual scent or off-flavor, a sign that the internal surfaces are clean and the flow paths are open.

After the final rinse, a short, practical validation follows. Reintroduce the funnel and run one more cycle with clean water, then let the machine rest for about 15 minutes before brewing the first regular cup. This brief pause is a quiet acknowledgement that hot surfaces and moving parts have reached a stable thermal and mechanical state after the descaling. It’s a small ritual, but it reduces the likelihood of a hot-start hiccup that can upset a service sequence or affect a batch’s flavor profile. You may find it helpful to document the date of the internal clean in a maintenance log, along with any observations about flow rate or pressure. In a high-volume environment, such records become a practical reference for scheduling the next maintenance window before a noticeable decline in performance occurs.

There is no universal timetable for internal cleaning because water quality, usage patterns, and the specific model influence the frequency. However, the core method—prepare a descaling solution, run a controlled soak, disassemble and clean the shower head and spray tube, and rinse until the aroma is gone—remains consistent. The technique is designed to be compatible with the most common commercial BUNN configurations, yet it should always be cross-checked against the official manual for your exact model. Model-specific instructions can vary in terms of reservoir capacity, the arrangement of bypass lines, or subtle differences in how the spray tube is integrated. The takeaway is clarity: the process is straightforward when you approach it with a clear sequence, the right tools, and a respect for the machine’s design.

As you perfect the internal clean routine, you begin to notice how the ritual aligns with broader maintenance. Cleaning internal passages is complemented by external cleaning of the machine’s surfaces and the carafe, which helps maintain overall hygiene and flavor integrity. In the same spirit of thoroughness, many operators keep a cadence of periodic professional cleaning products on hand—commercial cleaning powders or sheets to remove residual coffee oils, milk system cleaners for steam wands, and grinder cleaning tablets to address the burrs. While these products are not substitutes for the internal descaling described above, they support the machine’s ecosystem by preventing oil buildup from creeping into the brew path and by preserving the cleanliness of ancillary components that interact with the water and coffee. The goal is a kitchen- or back-of-house-wide cleanliness that respects the end cup every step of the way.

For operators seeking a consolidated reference, there is value in reviewing a detailed maintenance guide that consolidates model specifics, tool recommendations, and safety precautions. If you are exploring a deeper dive into the surrounding maintenance ecosystem, you can consult a practical, model-aware guide that mirrors the approach outlined here and expands on the ancillary steps. For a closely related, in-depth exploration of cleaning a BUNN machine, you can refer to the community-driven, step-by-step resource that covers similar terrain and offers practical tips learned from real-world kitchens. This broader reference can help you triangulate between the official guidelines and the lived experience of cafe technicians who routinely work with high-throughput brewers. A quick note: whenever you consult a guide that mirrors these steps, ensure the information aligns with your machine’s exact model and local safety standards.

If you want to see a concise, model-specific walkthrough in the context of a broader cleaning regimen, you can explore this focused guide that aligns with the internal-descaling approach described here. It is helpful to compare the approach to your current routine and to adapt the language to your own workflow while preserving the essential safety and effectiveness of the descaling process. For readers who want to cross-reference the steps with a formal product maintenance resource, there is a reliable destination that aggregates maintenance tasks and safety recommendations for commercial BUNN machines. The consistency of the process across different model families helps ensure that, regardless of the unit you operate, the essential actions—soak, scrub, rinse, and recheck—remain valid pillars of a robust cleaning program.

For ongoing learning and to keep your internal cleaning up to date with evolving best practices, you can also explore the more general guidance on how to maintain a commercial coffee system, which often includes model-agnostic advice on scale prevention, water treatment, and routine inspection. Such resources support a proactive stance, enabling you to anticipate common trouble spots before they impact service quality. The combination of internal descale and a steady external hygiene routine creates a durable foundation for reliable performance, consistent flavor, and smooth operation across the busiest service windows. The discipline of a well-executed internal clean is a form of preventive care that pays dividends in the flavor of your coffee, the efficiency of your team, and the longevity of the machine.

If you want to drill further into the exact steps tailored for your particular model, you can consult the official maintenance resources from the manufacturer. These documents are written with specificity for different hardware configurations and provide valuable warnings and tips that can save you time and avoid inadvertent equipment wear. In practice, merging official guidance with your operational know-how creates a resilient cleaning routine that can be integrated into shift handovers and nightly closures. The simple act of dedicating a scheduled internal clean becomes a reliable indicator that your coffee program is well-managed and responsive to the demands of a busy service.

To learn more about a precise, model-focused walkthrough and to compare notes with a larger body of practical experiences, consider reviewing the dedicated guide that discusses how to perform a comprehensive internal clean for a BUNN brew system. This resource emphasizes not only the mechanical steps but also the rationale behind each action, helping you communicate the process to staff and to align it with quality standards. For those who want to see how the internal clean fits into a broader cleaning routine, the guide also echoes the importance of consistent cadence and test brews after maintenance to verify that the machine returns to its expected performance profile. The knowledge is cumulative: a clean machine, a precise routine, and a culture of care that keeps every cup consistent from first to last.

For convenience and reference, you may wish to bookmark the official maintenance guide provided by the manufacturer. It collates model-specific instructions, recommended cleaning tools, and safety precautions, ensuring you have an authoritative source at the ready whenever you schedule a maintenance window. While the steps here map closely to those guidelines, the official manual is the definitive source for any subtle variations in your equipment, and consulting it helps prevent missteps when you encounter a nonstandard configuration. In the end, the internal clean is a practical, repeatable discipline that supports flavor integrity, equipment reliability, and a positive service experience for both staff and customers.

For readers seeking to refresh their technique with a peer-reviewed, example-driven narrative, a concise, accessible online companion exists that walks through the full cycle of descaling, component cleaning, and rinsing in a cafe setting. The resource reinforces the idea that the central act—soaking the internal paths with a descaling solution and then restoring clean flow—remains the core of effective maintenance. If you are curious about how other operators balance speed, safety, and thoroughness during these tasks, this companion piece provides context without compromising the precision required for a commercial brewer. It’s a practical complement to formal manuals and a reminder that a well-run cleaning protocol is as much about rhythm and hygiene as it is about chemistry.

To close the loop on the internal clean, keep in mind that a routine like this not only preserves flavor but also supports the operational life of the machine. The boiler’s integrity, the spray system’s accuracy, and the integrity of all wetted surfaces depend on disciplined maintenance. By following a thorough descaling and rinsing cycle, you reduce the risk of unexpected downtime, ensure a steady supply of hot water at the right temperature, and maintain the machine’s ability to deliver a uniform bloom in every cup. In the end, the internal clean is a quiet, steady commitment—a ritual that keeps the heartbeat of the coffee program strong even during the longest service days.

Internal linking note: for a detailed, machine-specific walkthrough that aligns with the approach described above, you can consult the dedicated guide that offers a focused, stepwise presentation. How to Clean a Bunn Coffee Maker. This resource mirrors the practical steps and reinforces the rationale behind each action, helping you translate theory into reliable practice in your own operation.

External resource: for a structured reference to maintenance practices and model-specific guidance, see the official maintenance guide from the manufacturer: https://www.bunn.com/support/maintenance

Polishing the Shield: External Care and Careful Shine for a Commercial Bunn Coffee Pot

In a busy commercial setting, the exterior of a coffee pot is more than a first impression; it’s a reflection of your operation’s standards and attention to detail. The metal, plastic, and glass surfaces do more than look polished. They bear the fingerprints of staff, the splashes of daily use, and the subtle telltale signs of climate and cleaning cycles. When the exterior remains clean and well cared for, it signals to customers that the equipment is well maintained, that sanitation is a priority, and that the team behind the counter is organized and professional. Cleaning the outside of a commercial coffee pot is not a decorative chore; it is a practical routine that protects finishes, prevents corrosion on metal parts, and reduces the transfer of oils and residue to beverages that pass through the machine. The task is simple, repeatable, and surprisingly impactful in high-volume environments where speed and reliability matter as much as flavor and aroma.

Begin with a clear plan and the right materials. You will need a soft, clean cloth that won’t abrade finishes; a small amount of mild cleaning solution or plain warm water; a separate dry cloth for final buffing; and a little patience. Avoid abrasive cleaners, scouring pads, or anything that could scratch the surface or leave behind residue. The point of the external routine is not to strip protective coatings or to create a mirror finish so bright that it distracts from the potential wear patterns over time. It is to strike a balance between cleanliness and preservation, keeping the equipment looking professional while extending its life. The approach is straightforward: wipe, assess, address stubborn spots with a gentle touch, dry, and return the unit to service with confidence.

Safety is the quiet backbone of any cleaning routine. Before you begin, confirm that the machine is unplugged and that all controls and indicator lamps have cooled. In many commercial models, the exterior panels abut electrical components or heat shields; moisture on those areas can introduce risk or damage. A damp cloth should be enough to lift most grime, but never drench a surface or allow liquid to pool around seams, cracks, or control interfaces. If the machine is mounted or partially recessed, take care not to tilt or press into surrounding equipment while you clean. A calm, methodical cadence—wipe, dry, step back to inspect—reduces the chance of overlooking spots and ensures you don’t miss the small places where oil, coffee, or fingerprints accumulate.

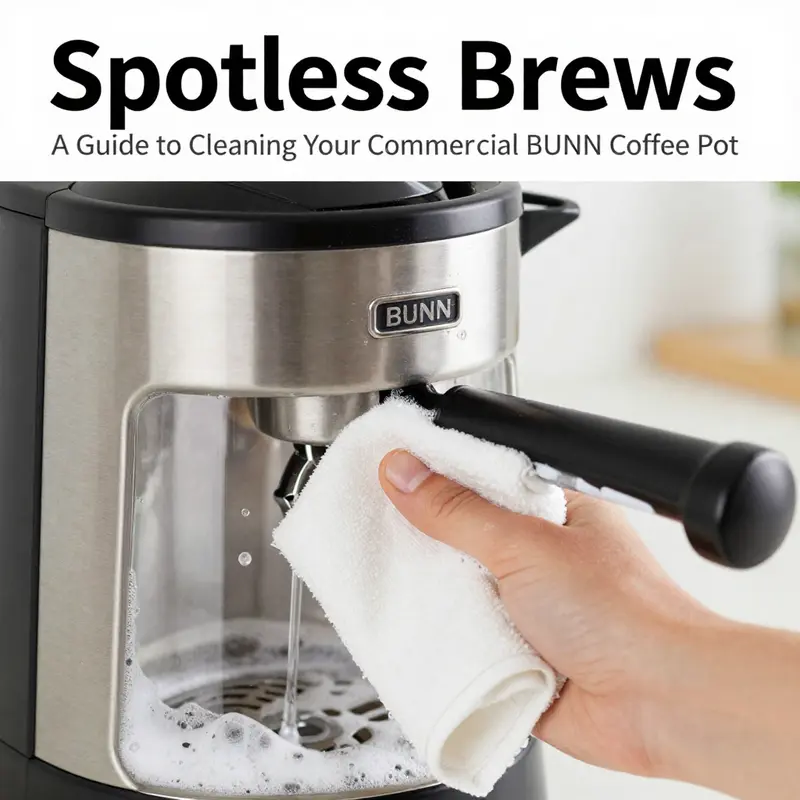

The daily exterior cleaning begins with a generous assessment of the visible surfaces. Start with the body of the pot, tracing from the top down to the base. Your aim is to lift oily residues and coffee dust that have settled on the finish. A soft, damp cloth is the workhorse here. Lightly moisten the cloth with warm water or a mild cleaning solution if stubborn stains resist a plain wipe. Work in small, overlapping circles to prevent smear lines and to help you see results as you go. Special attention should be paid to high-touch areas—the front panel, the lever or lid area, the corners of the drip tray housing, and the junctions where the body meets the base. These zones are where grime tends to collect fastest, and they benefit from more frequent attention in a high-use environment.

If you notice fingerprints, smudges, or a slight film along the stainless steel surfaces, you can opt for a mild cleaning solution, but test it on a small, inconspicuous area first. A simple solution of warm water with a drop of gentle dish soap can lift oily residues without leaving a slippery film. Wipe with the solution, then follow with a clean water rinse. It’s important that you remove all soap traces; even a faint film can attract more dust or alter the appearance of the finish. After the soap wipe, go over the surface with a dry microfiber cloth to remove any lingering moisture and to bring out a subtle sheen. A final pass with a dry cloth should leave no streaks and should enhance the natural luster of the metal or plastic surfaces without creating a glare under kitchen or service-area lighting.

For surfaces with tough odors or more stubborn staining, a touch of lemon-scented moisture can be pleasant while maintaining hygiene. A damp cloth with a few drops of lemon juice can freshen, but use this sparingly and avoid applying lemon directly to metal finishes that might be sensitive to acidity over time. The goal is a fresh scent that suggests cleanliness without risking discoloration or finish wear. If you prefer, you can simply use warm water and a mild detergent and rely on the odor-free rinse that follows to achieve the same effect. The point is to maintain a clean, inviting appearance without introducing elements that may damage the finish or leave a residue.

An area that deserves particular care is the cabinet under the work surface where the unit rests and the drip tray area. Coffee spills often collect around the drip tray lip and along the base, especially in a fast-paced service line. Remove the drip tray if your model permits it and inspect the tray well for any crusty coffee residues or oily patches that could transfer when the tray goes back in place. Wash the tray with warm, soapy water, rinse thoroughly, and dry before reinstalling. While the tray is out, wipe the surrounding base and the underside of the unit’s exterior with the damp cloth, checking for any spills or drips that may have found their way into crevices. A clean exterior on both the drip tray and the base is essential to uphold a cohesive, professional look and to cut down on the chance of residue interfering with the machine’s operation or the environment around the unit.

The hood or lid area, especially on models with hinged tops or pour spouts, benefits from a careful wipe that lifts film without pushing it into the hinge or seam. When you wipe near the control area, use a light touch and avoid directly pressing into buttons, switches, or display openings. This helps prevent moisture intrusion and keeps the control interface responsive. If you must reach into tight corners, a soft cloth wrapped around a small, flat tool can gently lift grime from crevices without scratching. Always avoid harsh solvents or abrasive tools that could wear the finish or degrade seals around access panels.

In practice, the rhythm of exterior care becomes a repeating cycle. Each day, a quick wipe-down lifts surface oils and dust; each week, a more deliberate pass targets fingerprints and smudges in trouble spots; and during busy periods, a rapid wipe after service helps maintain a consistently clean look. The aim is not to create a complicated ritual but to embed a discipline into the workday so that the exterior remains a source of pride rather than a reminder of the last spill. The best outcomes arise when every staff member understands that the exterior is part of the product. Clean surfaces communicate that your operation cares about every detail—from the beverage quality to the customer experience and the cleanliness of the environment in which drinks are prepared.

To support this routine with guidance that’s easy to apply, you can reference a concise, model-specific resource that outlines how to approach cleaning a Bunn coffee maker. For a detailed, step-by-step discussion that aligns with broader exterior care, see the dedicated guide on how to clean a Bunn coffee maker. That external reference can be a quick refresher if you need to confirm steps or recheck the scope of recommended materials. The approach remains straightforward: keep the outside free of oils, fingerprints, and residue; use mild cleaners when needed; dry thoroughly; and return the unit to service with a finish that looks fresh and professional.

As you clean, consider how this practice fits into broader maintenance. The exterior care you perform complements the descaling and internal cleaning routines that target the brew path, boiler, and spray mechanisms. When the outside stays clean, it’s easier to notice changes in the machine’s appearance that might signal wear or misalignment, such as unusual discoloration near seams, chips in the finish, or loosened panels. These are cues that deserve timely attention before a small issue becomes a more significant downtime event. The external surface acts as a visible health check for the equipment and, in a fast-paced setting, a quick visual confirmation that the unit remains in service-ready condition.

Incorporating these practices into a standard operating procedure helps ensure consistency across shifts. Create a simple checklist that staff can follow during each shift. The list might include: unplug the unit, remove the drip tray, wipe all exterior surfaces with a damp cloth, address fingerprints on high-touch areas, wipe down the lid and control area with a mild solution if needed, dry with a microfiber cloth, reassemble the drip tray, and perform a final visual inspect. A brief, repeatable checklist reduces the chance of skipped steps and supports a uniform presentation across multiple machines. When the team can rely on a consistent exterior finish, it’s easier to sustain a clean environment that supports both product quality and equipment longevity.

If your operation includes multiple stations or machines, the outside-cleaning protocol can scale gracefully. The same gentle technique works whether you’re maintaining a single unit in a storefront cafe or a row of pots in a high-volume catering kitchen. The key is to preserve the finish—avoid harsh chemicals, abrasive tools, or aggressive scrubbing—and to build the routine into the daily workflow so that the exterior remains in harmony with the machine’s internal cleanliness. In the long run, this practice helps reduce the frequency of deep, invasive cleanings that can require more downtime and specialized procedures.

For further guidance, you can explore the broader cleaning framework that covers both external and internal maintenance. A comprehensive resource on cleaning a Bunn coffee maker includes practical tips for descaling and for cleaning the throttle, spray head, and internal tubing, in addition to external care. While the internal procedures require more attention to safety and protocol, the external care described here is the companion practice that keeps the visible surface pristine between those deeper maintenance cycles. Returning to the idea of a unified routine, the exterior care you perform daily becomes a key part of a holistic program aimed at reliability, flavor consistency, and a professional image.

To connect this practice with a broader context, consider how the external care intersects with other maintenance activities. When you finish cleaning the outside, you can quickly verify that the machine’s footprint remains stable and that there are no loose components around the base. If a drip tray was removed for cleaning, ensure it is completely dry before reinserting to prevent water on the surface or sliding hazards. Make a mental note of any inconsistent gaps or signs of wear around seals; such observations deserve a closer look during the next detailed maintenance cycle. The practical effect of careful exterior cleaning extends beyond aesthetics. It helps preserve the integrity of the unit’s finish, reduces the likelihood of corrosion on metal parts, and supports a safer, more sanitary environment for the staff and customers alike.

In sum, external care for a commercial coffee pot is a disciplined, repeatable practice that dovetails with the more technical, in-depth cleaning routines. It requires only a soft cloth, mild moisture, and a little attention to detail. The ritual is swift enough to fit into a busy shift but thorough enough to make a meaningful difference in the overall appearance and condition of the equipment. When the exterior shines, it becomes a signal that every aspect of the operation—from the beans to the brew path to the customer’s experience—is treated with care. And that signal matters in a marketplace that prizes consistency, cleanliness, and reliability as much as it does roast profiles and beverage temperatures. For teams aiming to elevate their service standards, the exterior cleaning routine is a dependable, high-impact practice that complements the broader cleaning program and supports a resilient, professional operation.

Internal link reference: For a broader, more detailed walkthrough that includes additional methods and model-specific notes, you can consult the guide on how to clean a Bunn coffee maker, which offers a cohesive context for integrating exterior care with internal maintenance. how to clean a Bunn coffee maker.

External reference: For model-specific instructions and official recommendations, refer to the Bunn Axiom 15-3 Commercial Coffee Maker Manual. This resource provides authoritative guidelines that can inform any exterior cleaning decisions and ensure alignment with the manufacturer’s safety and care standards. https://www.bunn.com/support/manuals/bunn-axiom-15-3-commercial-coffee-machine-manual

Guarding Flavor, Speed, and Durability: A Thorough Guide to Maintaining a Commercial Brew Pot for Longevity and Peak Performance

Every commercial brewing system runs on habit as much as on heat and water. A busy café, a busy office, or a bustling workplace relies on a reliable, consistent cup, every time. The difference between a pot that ages gracefully and one that starts to stink of stale coffee or drops temperature mid-peak service comes down to maintenance that looks like routine and feels like discipline. In this chapter, we weave a single, cohesive narrative about maintaining a commercial brew pot designed for heavy use. The goal is not merely to clean but to protect the machine’s heart—the boiler, the spray system, and the interconnecting pathways—from mineral buildup, fluid residues, and wear, while also guarding the surface and carafe that frame the customer’s first impression of your beverage. The guidance here blends practical daily habits with deeper periodic care, all anchored in a respect for the machine’s design and a commitment to consistent performance.

A commercial brewer endures because operators embrace a rhythm. The rhythm begins with daily care that keeps the exterior and the accessible internals free of the immediate, obvious contaminants: coffee oils, grounds, and the splashes of steam that inevitably leave a film on metal and plastic surfaces. The exterior, the drip tray, and the grounds basket deserve attention because their cleanliness affects both flavor and workflow. A quick, consistent wipe down at the start and end of each shift prevents grime from becoming the thief of speed and accuracy. This habit is more than cosmetic; it reduces the chance that a clogged drip tray or a sticky control surface will slow service or mar a customer’s experience. The same daily routine extends to the brew head and shower screen. After each batch, a dedicated brush can scour away the oils that would otherwise cling to the shower’s delicate mesh. That is where the system meets the beans, and every droplet that travels through that shower screen has already met carbonic, mineral, and organic residues. Cleaning these components with care preserves the machine’s response time and the clarity of the coffee’s aroma in the cup that follows.

But daily care is only the opening act. A well-loved, high-volume brewer needs a more deliberate, periodic descaling strategy to battle mineral buildup. Water in many facilities carries minerals that, over time, form scale on the boiler and in narrow channels. Scale acts like a tiny, unplanned layer of insulation; it dampens heat transfer, slows flow, and can alter the temperature profile of a brew. The result is not merely a warmer or cooler cup but a shift in extracted flavors. A consistent descaling routine neutralizes these effects, restoring the machine’s performance to its baseline. In many kitchens and offices, the decision to descale monthly aligns with the natural cadence of a business cycle: after the monthly deep clean, when the machine has had time to settle into its routine, or on a low-demand week when maintenance can be scheduled without sacrificing service. The method chosen—vinegar, baking soda, lemon juice, or a commercially formulated descaler—depends on water hardness, tolerance for odor during the process, and the manufacturer’s guidance for your specific model. The key is to follow a defined ratio and contact time, then to rinse thoroughly until every trace of the cleaning solution is expelled from the system.

A practical descaling approach is to treat the internal network as a single system, from the reservoir through the boiler, across the spray tube, and into the shower head. Begin by preparing the descaling solution according to the chosen method. A classic, widely used option is a vinegar-water solution at a balanced 1:1 ratio. The process is specific: fill the reservoir with equal parts water and a mild, distilled white vinegar, then run the machine as if brewing into a carafe but stop when half the solution has passed into the container. After this, unplug the machine and allow the solution to sit inside the lines for a minimum of two hours. This dwell time is critical; it gives minerals time to loosen and detach from the metal surfaces, tubing, and joints. When the timer ends, the machine is reconnected, and the process resumes with a complete run-through of the remaining solution and then a thorough flush with fresh water. The rinsing phase cannot be rushed. It requires running several full cycles with clean water to remove all signs of vinegar or any other cleaner. A practical guideline is to perform three to four full rinses, discarding the water at each step, and then repeating until the room no longer holds onto a vinegar scent.

If vinegar is not preferred, there are viable alternatives. A measured mixture of warm water with a small amount of baking soda can serve as a gentle descaling agent, and a mix of lemon juice with water can provide not only cleaning power but a fresh scent. For those facilities that rely on stronger cleaning, a commercial descaling agent designed specifically for professional coffee equipment provides a proven alternative. Whatever solution is selected, the instructions in the product’s label, together with the machine’s manual, should guide the schedule, concentrations, and contact times. A disciplined approach here protects the boiler and the spray tubes from scale buildup that would otherwise compromise throughput and consistency, especially on busy shifts when the machine is in near-constant operation.

While the descaling solution works on the interior, the interior is not the only area that benefits from deliberate attention. The shower head—the part that disseminates hot water over coffee grounds—tends to accumulate scale and coffee oils that can clog the tiny holes. A deliberate, careful disassembly of the shower head is often necessary for a more thorough cleaning, though it must be done in accordance with the model’s manual. The process is simple in principle: remove the brewing funnel, unscrew the shower head by hand, and inspect the tiny holes for mineral deposits. A toothpick may be used gently to clear obstructions, and the exterior can be wiped with a damp cloth and a small amount of mild, fragrance-free dish soap. In hard-to-reach areas, such as the connection point, a pipe cleaner can be employed. It is essential to approach this step with respect for the machine’s design; the manual provides guidance on whether the shower head can be disassembled without voiding warranties or compromising seals.

Equally important is the spray tube—the conduit that carries water from the boiler to the shower head. When debris or scale accumulates here, the water’s path becomes constricted, influencing brew times and the uniformity of extraction. Cleaning the spray tube requires a small descaling tool or a slender brush that can be inserted into the tube. A careful back-and-forth rotation helps scrub the interior surface. This is not a one-shot job; bypass fittings and other tubing within the system may also require probing. After this internal cleansing, reassemble the shower head and reinsert the brewing funnel, ensuring that all components sit securely. The objective of these steps is not only cleanliness but unimpeded, consistent water delivery that supports even extraction across all pots or carafes during service.

Rinsing remains an ongoing theme because any cleaner residue left in the system can affect the flavor profile. After completing the descaling cycle, reassemble the machine, plug it back in, and run a full brew cycle with only fresh water. Discard this water, then refill with fresh cold water and repeat. The rinsing sequence should be performed three to four times, until the room no longer carries the chemical scent. High-volume environments benefit from documenting a standard rinse protocol that staff can follow to ensure uniform results regardless of who runs the machine. This discipline protects not just flavor stability but also the machine’s reliability; scale deposits that are repeatedly overlooked can over time contribute to pump strain, valve wear, or inconsistent temperatures—factors that erode throughput and guest satisfaction.

Beyond the internal machinery, external upkeep is not optional in a demanding café or office setting. The exterior surfaces should be wiped down with a soft cloth dampened with warm water and a dash of mild dish soap. Abrasive cleaners or scouring pads can scratch finishes and harbor microscopic ridges where oils collect. After wiping, a second pass with a clean, damp cloth removes any soapy residue, followed by a thorough dry with a clean towel. Some operators add a touch of lemon to the damp cloth to impart a fresh aroma; the effect is pleasant, but not essential. A neat exterior not only looks professional but also reduces the chance that dust and moisture will introduce contaminants into the brewing workflow.

The carafe, or glass pot, deserves consistent attention as well. After each use, a quick rinse with warm water helps prevent coffee stains from taking hold. Over time, stubborn staining can be removed with a deeper soak in warm water and dish soap, using a non-abrasive sponge to protect the glass. Thorough rinsing and complete drying are important because even a left-behind trace of moisture can encourage mineral deposition or microbial growth when the carafe rests in its warming plate. If a carafe develops etching or persistent staining, a dedicated cleaning routine can restore clarity and transparency. For high-volume settings, the carafe may be treated as a workhorse that deserves more frequent deep clean cycles without interrupting service; keeping the carafe spotless contributes to the perception of hygiene and quality customers expect.

A broader maintenance framework helps a busy operation stay on track. A monthly deep clean, supported by the descaling steps outlined above, should be complemented by routine checks of the machine’s major components. Regular inspections of filters, gaskets, and seals are essential; worn seals can lead to leaks or pressure loss, which in turn affects brew times, temperature stability, and flavor consistency. The goal is not to replace parts at the first sign of wear but to identify patterns and intervene before a small issue becomes a costly downtime event. The maintenance plan should align with the user manual’s guidance on part numbers and replacement intervals. This alignment ensures that any replacement parts fit properly and preserve the machine’s safety features and performance characteristics.

In the realm of maintenance, the difference between a smooth operation and a hiccup often lies in adopting brand-approved procedures. The manufacturer’s recommendations are designed to preserve the machine’s performance envelope and to minimize the risk of damage from improvised cleaning. Following model-specific instructions helps avoid inadvertent harm to seals, gaskets, and electronic components that could compromise safe operation. While the core concepts of cleaning and descaling are universal, the exact measurements, recommended products, and procedural nuances can vary between models. For readers who want a concrete, model-tailored walkthrough, a practical, brand-focused companion resource exists that distills these processes into actionable steps. This resource complements the guidance here and provides a reliable cross-check to ensure the correct procedures are followed on your particular unit. How to Clean a Bunn Coffee Maker.

In addition to the routine and periodic care described, it pays to think about maintenance as part of a broader operations strategy, especially in high-volume settings. Documentation matters. Keeping a simple maintenance log—date, tasks performed, parts inspected or replaced, any anomalies—helps teams recognize patterns and plan preventive interventions. A clear log supports staff accountability and gives managerial leadership a practical view of the equipment’s condition over time. When teams approach maintenance as a shared responsibility rather than a reactive task, the machine’s reliability rises, and service interruptions decline. The coffee program becomes less about chasing problems and more about sustaining a consistent experience that customers can count on, shift after shift.

The goal of all this care is not merely the absence of technical problems but the presence of a reliably bright and balanced brew. When the internal channels remain free of mineral buildup, when the spray system delivers water evenly across the coffee bed, and when the carafe and exterior shine with professional polish, the user experience remains consistent. Flavor remains faithful to the beans’ profile, the machine returns to temperature quickly after a batch, and service times stay predictable. The operator’s confidence grows as the machine’s performance stays within a narrow, expected range. Over time, the routine becomes almost invisible—a quiet, steady background that supports the cafe’s or office’s daily rhythm rather than intruding upon it. This is maintenance as a competitive advantage: a commitment to longevity that translates into sustained throughput, stable flavor, and a reliable front-line operation that customers and staff can trust.

To bring all these threads together, consider the broader ecosystem in which the machine operates. The water supply, the supply of cleaning agents, the schedule of routine maintenance, and the competency of staff all converge to determine the brewer’s health. Water hardness, in particular, is a significant, often overlooked variable. In areas with hard water, scale forms more rapidly, demanding more frequent descaling or the use of water treatment solutions. In softer-water environments, the internal scale may grow more slowly, but still requires attention to maintain performance. A responsible program accounts for these environmental differences, adjusting the cadence of deep cleans and the choice of descaling agents accordingly. The best maintenance plans reflect a balance between universal best practices and the realities of the local water chemistry and usage patterns. This balance ensures the machine remains a reliable tool rather than a source of unexpected downtime or flavor drift.

For those who want to ground these practices in a concrete, step-by-step framework, a concise reference exists in the broader body of resources associated with this topic. The guidance emphasizes three pillars: daily care that keeps the visible surfaces clean and the brew head unclogged; periodic descaling that preserves heat transfer and flow; and periodic inspection that guards against leaks and seals wear. When aligned, these pillars form a coherent program that can be taught to new staff, reviewed during shift handovers, and audited during maintenance cycles. The result is a working culture where cleanliness, reliability, and flavor are not separate concerns but a unified standard that everyone upholds.

As you implement or refine your maintenance routine, you may find it useful to cross-reference practical, model-specific guidance. A reliable, reader-friendly resource offers a structured walkthrough tailored to the machine’s design and configuration. It complements the high-level practices described here and serves as a practical checklist you can keep near the brewer during cleaning sessions. By keeping this resource in view, staff can confirm that each step is performed correctly and that no critical detail is overlooked during busy shifts.

In the end, maintenance is about stewardship. It’s about treating the commercial brewer not as a disposable workhorse but as a durable piece of equipment that helps your team deliver quality coffee consistently. It’s about creating a predictable workflow, a clean sensory baseline, and a service experience that feels effortless to customers and staff alike. The approach outlined here—an integrated blend of daily hygiene, thoughtful descaling, careful internal cleaning, and proactive inspections—paves the way for reliable performance and a long, productive life for your brewing system. When the routine is clear, when the tools and supplies are well organized, and when the team understands the why as well as the how, the machine becomes a stable foundation for great coffee day after day. This is the essence of longevity and performance: a disciplined, ongoing commitment to care that pays dividends in flavor, consistency, and uptime.

External resource for deeper reference: Official Axiom 15-3 User Manual.

Final thoughts

A well-maintained BUNN coffee pot not only preserves the quality of your coffee but also ensures your business runs smoothly and efficiently. By regularly cleaning both the internal and external components of the machine and adopting maintenance strategies, you can prevent unwanted breakdowns and enhance the longevity of your equipment. Following the outlined methods in this guide will keep your BUNN coffee pot performing at its best, allowing you to focus on delivering exceptional coffee experiences to your customers.